-

Cellular Phones

Cellular phones are still a thing, but they’re not nearly as popular as they once were. Those who manufacture cellular phones require a lightweight camera PCB assembly to incorporate into their phones. Cell phones with cameras are still very popular, and many people use them to take pictures or record videos.

-

Surveillance Systems

Surveillance systems are also popular, and they require a camera PCB assembly to be installed. Surveillance systems can be used for security purposes or to monitor the activity of people who work in an enclosed space such as an office building or a home. Resolution is one of the most important factors that determine the quality of a camera. The higher the resolution, the better the recording CCTV cameras can offer.

-

Medical Devices

Medical equipment such as endoscopes, laparoscopes, and dental cameras also require a camera PCB assembly. These devices need to be able to produce high-quality images that can be used for diagnosis and treatment purposes. Unlike other applications, PCB assemblies for medical devices should be able to withstand high temperatures and be resistant to chemicals.

-

Tablets

A child-friendly tablet with low prices and high-quality features is something everyone is looking for. The importance of having a tablet PC in every child’s hands is essential. To make this possible, manufacturers require a camera PCB assembly that is designed for mass production and can be embedded into the tablet’s design. Tablets require lower resolution compared to other applications because they are mainly used for browsing the internet, social media, and playing games.

-

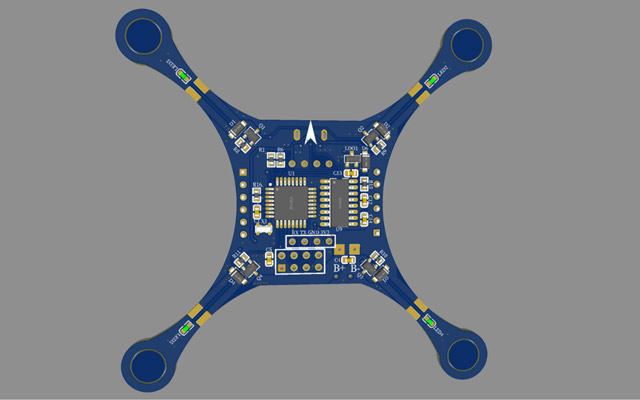

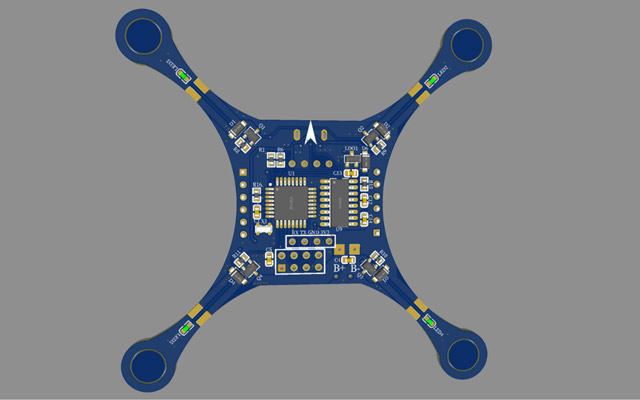

Drones

Arguably one of the most popular applications for camera PCB assemblies is drones. Drones are used for a variety of purposes, such as photography, videography, and even security. Many drones come with HD cameras that are able to capture high-quality images and videos. Drone manufacturers require a camera PCB assembly that is lightweight and able to withstand the vibration of the drone’s engines. This should also be able to connect to the drone’s flight control system.

-

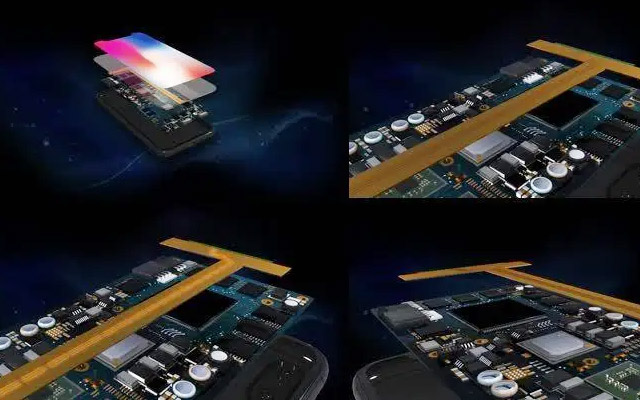

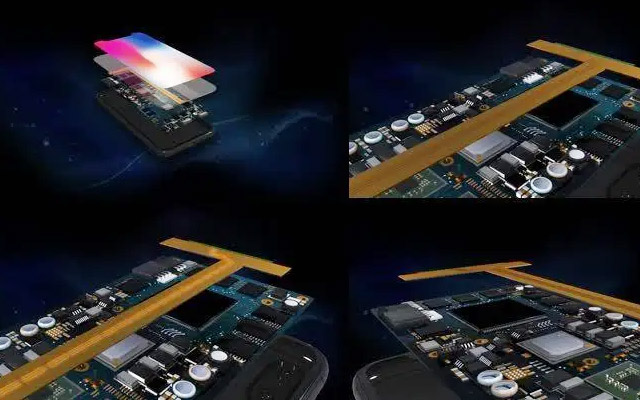

Smart Phones

The use of smartphones has increased dramatically in recent years, and many people use them for a variety of purposes. Smartphones usually have a built-in camera, and the quality of the camera is arguably one of the most important factors that people consider when buying a phone. Smartphone manufacturers require a camera PCB assembly that is small and lightweight so that it can be easily embedded into the phone’s design.