-

Aerospace

Much appreciated for their exceptional capacity to handle the stretch of extraordinary temperatures and vibrations, flex PCBs are extraordinarily suited for Aerospace applications such as satellites. They too can take on abnormal shapes that are well suited for shuttle and substituting connectors that are more inclined to disappointment.

-

Commercial Electronics

A third of the deals volume for adaptable printed circuits comes from computer innovation everything from printers, scanners, shrewd devices, and more. With the advertising driving for littler and more progressed handheld innovation, rigid-flex PCBs are fundamental for overwhelming computing control without relinquishing weight confinements.

-

Laptop, Computer, and Tablet

Numerous computers, laptops, and tablet components depend on adaptable circuit boards for operation. Computer devises today tend to be little and lean and can in some cases reach tall temperatures. You'll be able to discover adaptable circuit boards in numerous other buyer electronics applications as well counting TVs, gaming systems, printers, and microwaves.

-

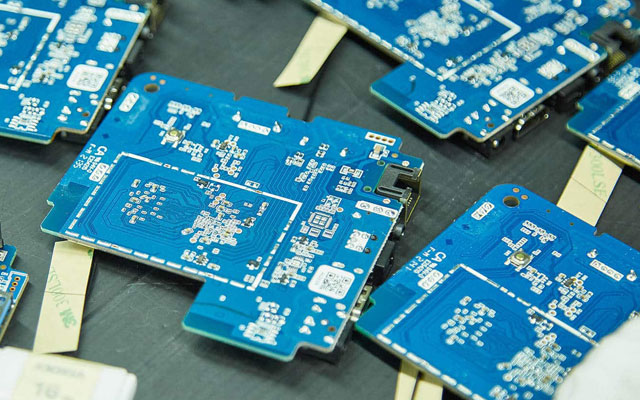

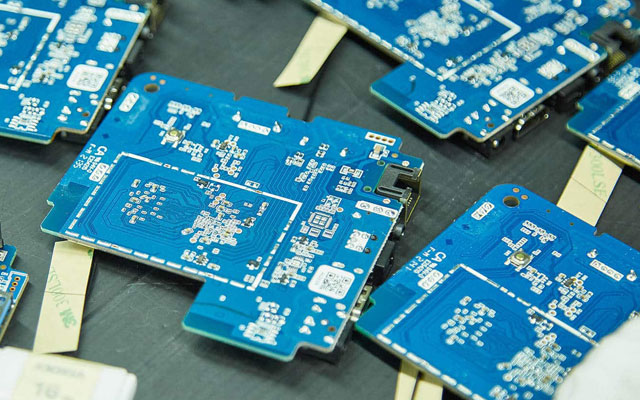

Smartphones

Smartphones are idealized candidates for flexible circuit boards. They are handheld, so they have to stay little, lightweight, and portable. A single, thin-layer board is required to put through and adjust all center components. Smartphones are presently frequently outlined with water-resistant and waterproof repulsing cases planned to permit the phone to work whereas and after its contact with the fluid.

-

Medical Devices Field

These medical devices are vital for pharmaceutical and medical applications, particularly when those circuits must survive extraordinary conditions in the interior human body. Analysts have moreover created a preparation for printing circuitry onto an adaptable, natural material that can be embedded within the body to make more reasonable prosthetic appendages.

-

Automotive Electronics

When it comes to advanced automobiles, the majority of their electronic equipment uses adaptable printed circuit boards. This incorporates EMUs (motor services units or computers), anti-lock braking frameworks, discuss pack controllers, instrument boards and sprint frameworks, and much more.