-

Consumer Electronics

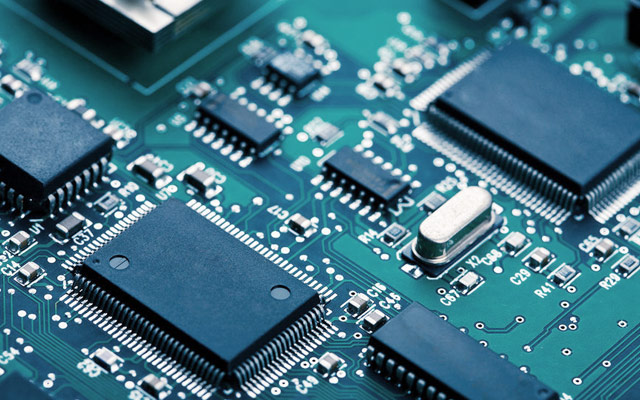

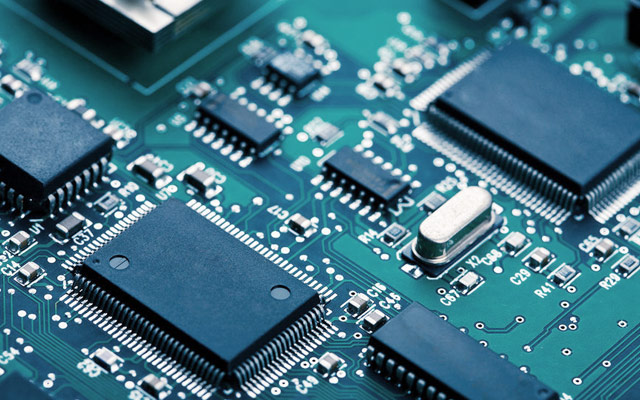

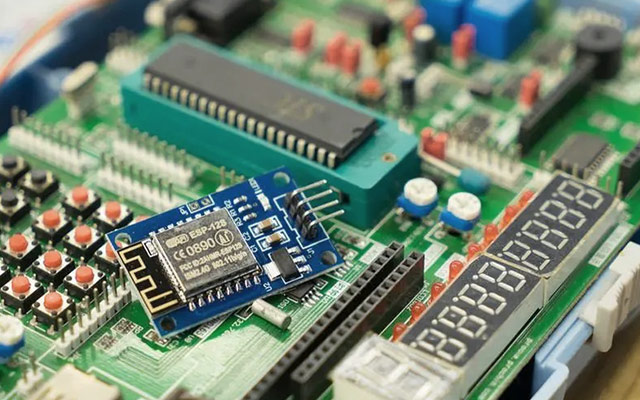

Electronics manufacturing utilizing SMT basically implies that electronic components are gathered with computerized machines that put components on the surface of a board PCB. Surface Mounted Technology components are put straightforwardly on the surface of the PCB rather than being patched to a wire lead. When it comes to electronic assembly, SMT is the foremost regularly utilized handle within the industry.

-

Telecommunications

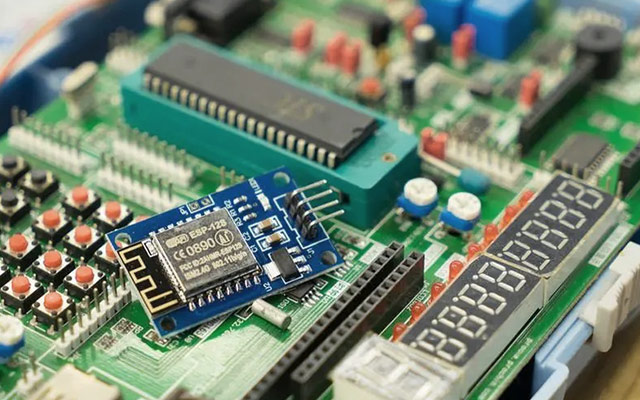

The warm trades of SMT appear and pointers have made contrast within the advance of the value of versatile communications contraptions. Regularly, overheated screens will lead to development hurt to the circuitry of the contraption itself. SMT assembly have made a distinction in certainly diminishing the number of breakdowns found in these devices.

-

Medical Devices

Surface Mount Technology assembly services are crucial for pharmaceutical and medical applications, especially when those circuits must survive exceptional conditions within the insides human body. Analysts have in addition made planning for printing circuitry onto a versatile, normal material that can be embedded within the body to create more sensible prosthetic members.

-

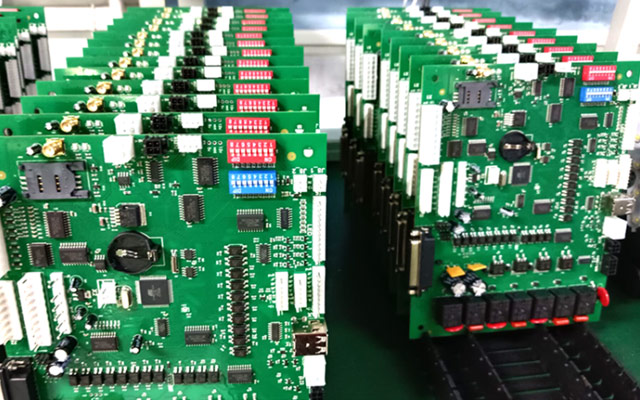

Industrial Control Systems

Surface Mount Technology Assembly Service was also used for industrial control systems. This technology gives a wider extent for machine vibrations and temperature that is applicable for big industrial machinery and technology. SMT Assembly Services has also made distinctions in diminishing the number of breakdowns found in these industrial control systems.

-

Aerospace

Much acknowledged for their extraordinary capacity to handle the extent of uncommon temperatures and vibrations, flex PCBs are exceptionally suited for SMT assembly applications such as satellites. They can also take on irregular shapes that are well suited for carrying and substituting connectors that are more slanted to disillusionment.

-

Defense Systems

Our in-depth information on different military application prerequisites permits us to collect SMT assembly services made from distinctive composites, materials, and substrates. Each SMT assembly goes through nitty assessment preparation that incorporates circuit board testing, component review, user testing, and indeed manual assessment, in the event that is required.